High Capacity Industrial Food Waste Recycling System Manufacturers

Product Description:

Our organic waste converter serves the dual purpose of food waste management and making a productive supplement from it. This will help you to easily overcome your waste management woes and at the same time be a part of our humble attempt to keep the environment clean.

Waste management is an investment in the ecology as well as the future. Soon industries that produce a lot of organic wastes like hotels, restaurants, flight kitchens, caterers, malls, apartments, canteens will need to start managing their own waste. If not taken care of, food waste management can create headaches for your business and hinder your path to progress.

Output Product: Organic Fertilizer

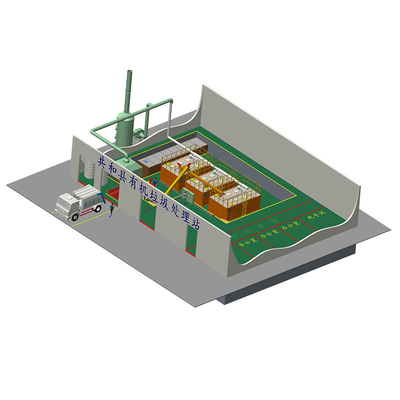

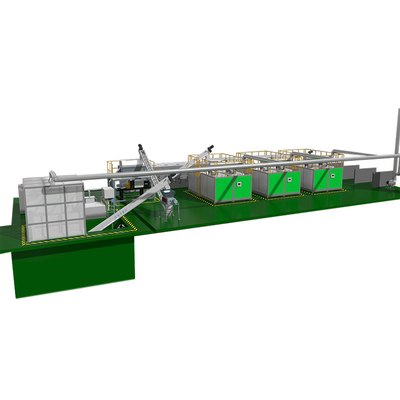

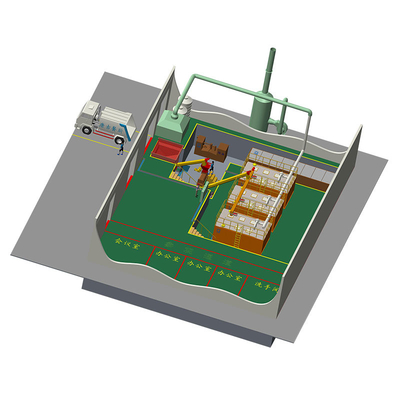

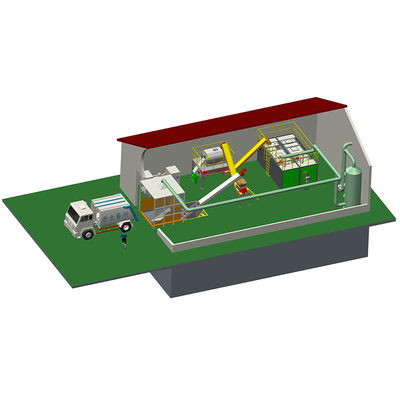

Main Process: Dumping → Sorting → Discharge Auger Conveyor → Shredding → Solid-Liquid Separation → Oil-Water Separation → Fermentation → Deodorization → Output

| NO. |

Item |

Parameter |

| 1 |

Model |

TG-CC-10T |

| 2 |

Rated Capacity |

≥10T/Day |

| 3 |

Waste Reduction Rate |

≥90% |

| 4 |

Ambient Temperature |

-10~40℃ |

| 5 |

Electrical System (Installation of Independent Meter) |

380V |

| 6 |

Processing Cycle |

24H |

| 7 |

Processing Method |

Microbial Fermentation and Hot Air Drying |

| 8 |

Control System |

Automatic Control System |

| 9 |

Heating Mode |

Electric Heating, Water Heating |

| 10 |

Fermentation Temperature Control Range |

65~75℃ |

| 11 |

Feeding Mode |

Continuous or Intermittent |

| 12 |

Noise |

65dB |

| 13 |

Coverage of Facilities |

Provided on site |

| 14 |

Main Material |

304 stainless steel is used for the main body and the part contacting materials. |

| 15 |

Host Panel |

Stainless steel, no obvious dents, scratches, and burrs, no sharp edges and corners. |

Process Principle:

The processing time of the whole fermentation process is about 24 hours, and the reduction rate is more than 90%. There is no need to add other organic matter and nutrient solutions.

The organic waste is put into the fermentation bin after collection, unloading, crushing, solid-liquid separation, and oil-water separation. High-temperature fermentation and auxiliary heating are used to keep the temperature in the warehouse at 65 ℃ ~ 75 ℃, and the fresh air required for fermentation is always maintained in the warehouse through gap stirring.

The energy released in the fermentation process is treated by the deodorization system and discharged in the form of gas and water vapor, which effectively eliminates odor pollution and avoids secondary pollution in the process of treating organic waste pollutants. After simultaneous high-temperature and rapid fermentation, only about 10% of non-toxic and harmless organic fertilizer substrate is left. The fertilizer can be used as an organic soil conditioner to modify the soil, improve the utilization rate of chemical fertilizer, fertile soil, increase production.

Working Process:

1. Open the lid from where the waste would be placed in.

2. Place in the waste. Make sure the waste is segregated and only organic waste is being put

inside the machine.

3. Close the lid and the machine would start its operation of converting the waste into Soil

Enricher.

FAQs:

1. What happens if I over load it?

We would recommend not to overload the machine but in case it gets overloaded, the in-built sensors would not allow the machine to start the operation to protect the machine.

2. What can I do with the compost?

The compost can be used in one of the following ways:

-

It can be used for the gardens in the premises as a soil nutrient.

-

It can be sold to the fertilizer companies or on e-commerce websites like Amazon where it can fetch Rs. 50/Kg or more.

-

It can be donated to the nearby nurseries or to the farmers and you can be a contributor to the development of the nation.

-

A local government body might collect the compost depending upon where you are.

3. Does it need to be on 24 hours?

Yes, the machine has to be connected to the source for 24 hours. However, it consumes power only from 8 to 11 hours depending on the humidity content of the waste. However, the air supply blower and the electronic circuit would operate for 24 hours.

4. What happens if I have a power cut?

If there is a power cut, the machine would start cooling down. However, today, all the societies, hotels, restaurants, hospitals, municipalities have the power back-up facilities and we recommend using the power back-up via a power generator to keep the machine running. However, the power failure would not affect the equipment.

5. Does TOGO give out any harmful gases?

No gases as there is aerobic digestion taking place i.e. continuous air intake and air outlet.

6. Is TOGO heavy on maintenance?

As there is no crushing or grinding involved in the process, no wear and tear of inner parts takes place. Also the main tank is made up of stainless steel (SS304 Grade), which adds to its long lifespan. Thus, no maintenance as such is required.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!