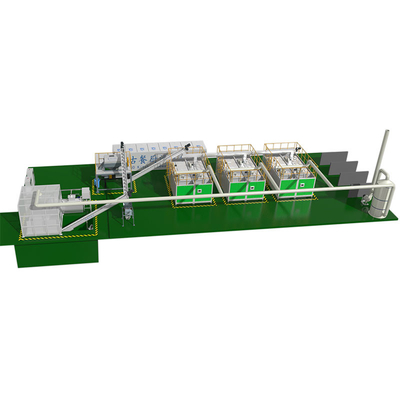

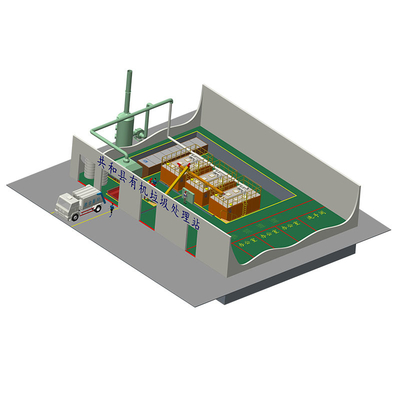

Larger Volumes Food Recyclable Organic Food Garbage Composting System

Product Description:

TOGO's innovative technology allows for an automated and odorless composting process. Our exclusive microbes along with heat, transforms ordinary food waste into nutrient-rich soil. Our solutions are energy-efficient and a "hands-off" automated process.

Rapid breakdown of organic materials is our specialty!

Our machine's one-touch control is fully automatic, sensing composting status and providing feedback and controls the operation without pre-setting a timer.

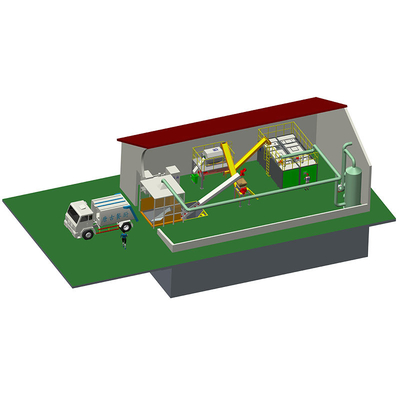

Main Process: Dumping → Sorting → Discharge Auger Conveyor → Shredding → Solid-Liquid Separation → Oil-Water Separation → Fermentation → Deodorization → Output

| NO. |

Item |

Parameter |

| 1 |

Model |

TG-CC-10T |

| 2 |

Rated Capacity |

≥10T/Day |

| 3 |

Waste Reduction Rate |

≥90% |

| 4 |

Ambient Temperature |

-10~40℃ |

| 5 |

Electrical System (Installation of Independent Meter) |

380V |

| 6 |

Processing Cycle |

24H |

| 7 |

Processing Method |

Microbial Fermentation and Hot Air Drying |

| 8 |

Control System |

Automatic Control System |

| 9 |

Heating Mode |

Electric Heating, Water Heating |

| 10 |

Fermentation Temperature Control Range |

65~75℃ |

| 11 |

Feeding Mode |

Continuous or Intermittent |

| 12 |

Noise |

65dB |

| 13 |

Coverage of Facilities |

Provided on site |

| 14 |

Main Material |

304 stainless steel is used for the main body and the part contacting materials. |

| 15 |

Host Panel |

Stainless steel, no obvious dents, scratches, and burrs, no sharp edges and corners. |

What are turning units of composting and how do they work?

Turning units are systems designed to be turned or aerated. These units work faster than holding units, because aerobic bacteria are provided with the oxygen they need to break down materials. There are two general forms of turning units: either a series of bins, a rotating barrel or rolling ball. When organic materials are turned and mixed on a regular basis (every five to ten days), compost can be made in two months or less (assuming a good carbon/nitrogen mix and proper moisture content). Frequent turning offers important advantages in addition to faster composting. Higher temperatures produced as a result of turning (90° – 140° F) will kill major disease organisms and fly larvae, help kill weed seeds and provide a good environment for the most effective decomposer organisms.

Working Process:

- The dump truck dumps the organic waste into the discharge hopper.

- The organic waste pours into the moving belt and goes forward, the operator can sort the foreign such as metal, plastic bag out.

- The shredder machine will cut the organic waste, then the shredded organic waste will convey to the dewatering squeezer, extrusion dehydration.

- Finally, the shredded and dewatered organic waste will fall off to the auger conveyor, then the auger conveyor will convey the solid organic waste to the fermenter to do digestion.

FAQs:

1. What can I do with the compost?

The compost can be used in one of the following ways:

-

It can be used for the gardens in the premises as a soil nutrient.

-

It can be sold to the fertilizer companies or on e-commerce websites like Amazon where it can fetch Rs. 50/Kg or more.

-

It can be donated to the nearby nurseries or to the farmers and you can be a contributor to the development of the nation.

-

A local government body might collect the compost depending upon where you are.

2. What happens if I over load it?

We would recommend not to overload the machine but in case it gets overloaded, the in-built sensors would not allow the machine to start the operation to protect the machine.

3. How many times a day can I load waste into it?

We recommend that the waste should be loaded once in a day for smooth operation of the machine.

4. Does it need to be on 24 hours?

Yes, the machine has to be connected to the source for 24 hours. However, it consumes power only from 8 to 11 hours depending on the humidity content of the waste. However, the air supply blower and the electronic circuit would operate for 24 hours.

5. What happens if I have a power cut?

If there is a power cut, the machine would start cooling down. However, today, all the societies, hotels, restaurants, hospitals, municipalities have the power back-up facilities and we recommend using the power back-up via a power generator to keep the machine running. However, the power failure would not affect the equipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!