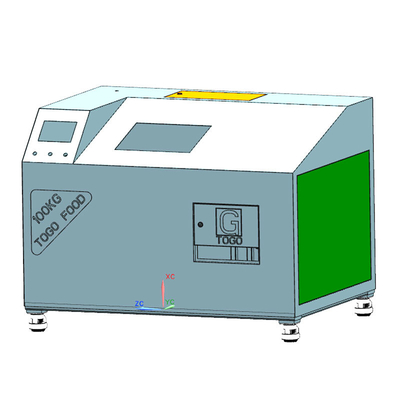

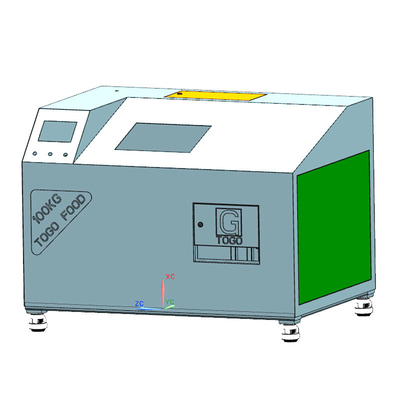

Famous Brand Automatic Kitchen Garbage Food Waste Recycling Equipment

Product Description

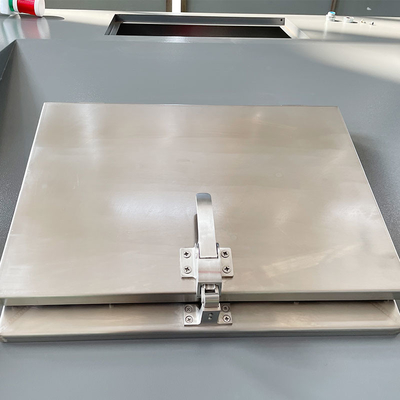

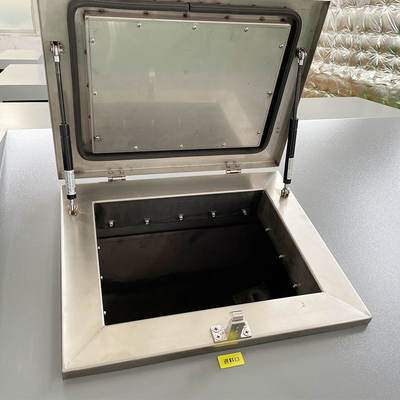

- Our wet waste composting machine adopts unique stainless steel + Q235 paint, beautiful appearance, compact structure, small footprint, and long service life.

- The machine adopts SIEMENS touch screen interface operation mode, PLC control, and automatic operation, without manual duty, the real-time temperature of the fermentation tank can be displayed on the touch screen. Big data remote monitoring, a mobile phone can also strictly control the operation status of monitoring equipment.

- It is suitable for small and medium catering / commercial complexes and other sources of wet garbage.

Product Advantages

- The kitchen waste composting machine equipment adopts unique stainless steel + Q235 paint, beautiful appearance, compact structure, small footprint, and long service life.

- Simple operation, fully automated operation, no manual sorting.

- Less investment, low operating cost, small footprint.

- No odor emission, no sewage discharge, no secondary pollution, no harm, and resource utilization during the operation of the equipment.

- The equipment adopts self-developed full PLC touch intelligent control and an online monitoring system. The main components are Schneider and LCD screen, Schneider. The operation interface is clear and simple.

- The food and kitchen waste reduction is about 85-90%, and the output (soil conditioner) product indicators have reached national standards.

Machine Parameters

| Model |

TG-CC-100 |

| Function |

Fermentation & Deodorization |

| Daily Processing Capacity |

100KG/Day |

| Processing Cycle |

24H |

| Processing Method |

Microbial Decomposition |

| Reduction Rate |

90% |

| Service Life |

100000H |

| Noise |

≤65dB |

| Ambient Temperature |

45-75℃ |

| Power |

5.3KW |

| Voltage |

380V, 50/60Hz |

| Power Consumption |

25KWH/D |

| Contact Parts Material |

SUS304 |

| Appearance Material |

Q235B + Appearance Painting |

| Control Method |

Fully Automatic PLC + Touch Screen |

| Machine Weight |

640KGS |

| Machine Size |

1600*1300*1340mm (L*W*H) |

| Optional Device |

Shredder Machine, Dewatering Machine |

Working Principle

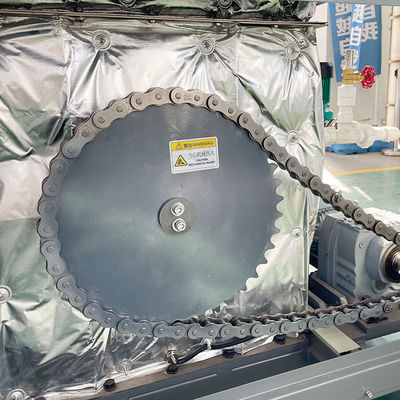

Use microbial strains to produce a variety of enzymes, which can quickly sort out wet waste (such as vegetables, vegetable leaves, vegetable roots, food residues, chicken, duck and fish meat waste, shrimp and crab shells, egg shells, bones and swill) break down. After treatment, the reduction rate of kitchen waste is 85-90%. After setting the operating parameters, it can be automatically operated for 24 hours. During the operation of the equipment, the exhaust gas reaches the standard and the sewage meets the standard. The remaining 10-15% of solid emissions can also be used as base fertilizer for organic fertilizers for fruit and vegetable cultivation. The whole process is pollution-free and there is no secondary pollution. It is in line with the principle of “reduction, harmlessness and recycling” of national waste disposal.

Why is Food Waste a Problem?

- Food waste landfills are one of the largest man-made sources of methane and H2S (a strong greenhouse gas). Once thrown into a landfill, food waste does not decompose and instead, adds to the toxic soup in the landfill.

- Our food waste contains a huge amount of valuable nutrients that should be returned to the soil as compost, which enriches it and helps to grow more food. It is such a natural simple cycle which our ‘developed’ world has lost sight of. TOGO Composter Machine is an ideal solution as it allows us to keep value in our own food ‘waste’.

- Laziness and convenience have encouraged people to see leftover food as ‘waste’ but we need to change this view. Composting needs to become the norm for all our society’s food waste.

Food Waste Is Unique as a Compost Agent

Food waste has unique properties as a raw compost agent. Because it has a high moisture content and low physical structure, it is important to mix fresh food waste with a bulking agent that will absorb some of the excess moisture as well as add structure to the mix. Bulking agents with a high C:N ratio, such as sawdust and yard waste, are good choices. Food waste is highly susceptible to odor production -- mainly ammonia -- and large quantities of leachate. The best prevention for odor is a well-aerated pile that remains aerobic and free of standing water. Leachate can be reduced through aeration and sufficient amounts of a high carbon bulking agent. It is normal to have some odor and leachate production. Captured leachate can be reapplied to the compost.

What are turning units of composting and how do they work?

Turning units are systems designed to be turned or aerated. These units work faster than holding units, because aerobic bacteria are provided with the oxygen they need to break down materials. There are two general forms of turning units: either a series of bins, a rotating barrel or rolling ball. When organic materials are turned and mixed on a regular basis (every five to ten days), compost can be made in two months or less (assuming a good carbon/nitrogen mix and proper moisture content). Frequent turning offers important advantages in addition to faster composting. Higher temperatures produced as a result of turning (90° – 140° F) will kill major disease organisms and fly larvae, help kill weed seeds and provide a good environment for the most effective decomposer organisms.

Turning systems typically cost more than holding units and require greater effort to build. Turning composting materials in multiple bins and rolling balls may be difficult for people with back problems or limited physical strength. In contrast, some barrel units are designed for ease of turning and maintenance. These systems may actually be easier to use than holding units for older or physically challenged composters. Barrel units tend to have smaller capacities than most other bins, which make them better suited for people with small amounts of yard trimmings and food scraps.

Materials need to be carefully prepared and added to turning units in stockpiled batches. Materials should be saved until there is enough to fill one bin of a multiple unit or to fill a barrel unit to the prescribed level. Food wastes can be accumulated in a pest-proof container such as a plastic five gallon bucket. If necessary, sawdust can be added to the top of each day’s scraps to reduce odour.

What happens if the machine is loaded with excess material?

TOGO Composter is designed to handle 20% excess material. However, if more organic waste is loaded, output compost will not be fully cured. Also, there are chances of foul smell.

Does it need to be indoors?

No, it need not be indoors, however, being an electrically operated machine, it has to be kept covered in a shed for the safety of the operator during the monsoons.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!